bagaimana bisa kita membantu kamu

The two-hand button is a commonly used safety start device, which is commonly used in punching machines, presses, cutting machines and other equipment; the purpose is to force the operator to keep his hands away from the dangerous area when driving the machine, so as to avoid contact with dangerous moving parts and cause safety accidents .

The "standard theory" of two-hand control

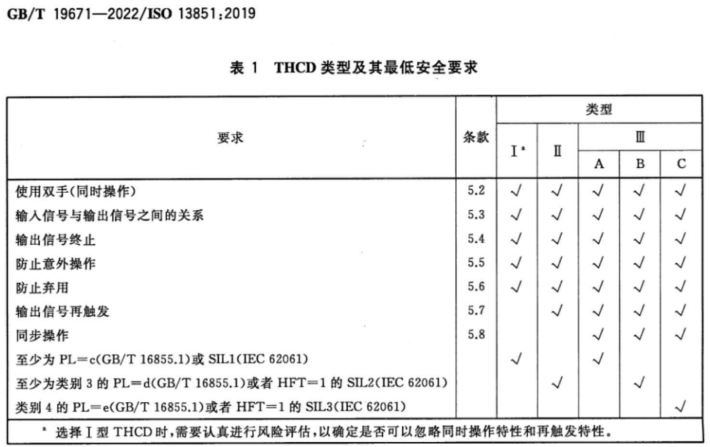

Two-hand control is not simply a control of pressing two buttons, it actually has special relevant standards to refer to. Three types of two-hand controls are specified in ISO 13851 (GB/T 19671-2022 Principles for Design and Selection of Two-hand Control Devices for Mechanical Safety), namely Type I, Type II and Type III, which are suitable for different safety requirements. in different scenarios.

When the two-hand control needs to meet the safety level above PLc required by ISO 13849-1 (GB/T 16855.1), a Type III two-hand control device must be used, and its function needs to meet three key points:

1. You need to use both hands to continue to operate, release any one or two buttons, and immediately terminate the output

2. The time difference between pressing both hands is less than 0.5 seconds. If it exceeds this time, you need to release the two-hand button and press it again

3. Only after both buttons are released can the output be triggered again (that is, only one button is released and pressed again will not perform the output); and there are also dual channels for Type IIIC type two-hand control devices (corresponding to PLe safety level) and detection of contact faults and other requirements

Combined with the above requirements, two-hand buttons usually need to be used with a dedicated two-hand button controller (two-hand button safety relay). In addition to the safety function requirements of two-hand control on a piece of equipment, there are often emergency stops, safety doors, safety light barriers, etc. There are many requirements for safety functions, and more complex applications can use programmable safety controllers, such as our PNOZ multi series safety controllers; for simple applications, such as only one emergency stop and two-hand control, generally speaking It is to match the emergency stop with a safety relay, and then realize the logic control between the emergency stop and the two-hand button through wiring.

New solution for simple applications

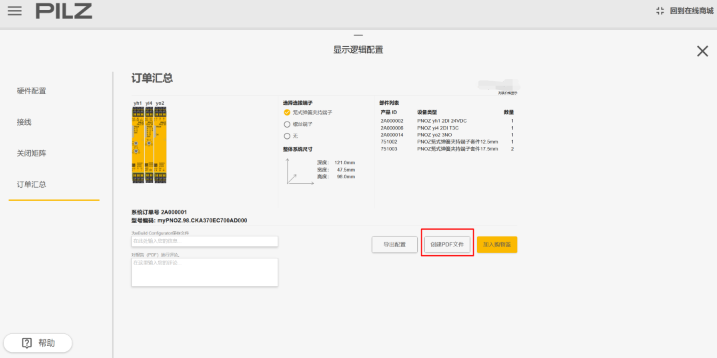

For simple two-hand control applications there is now an even more flexible and efficient option - the modular safety relay MyPNOZ. This is a security solution that can be "tailored" according to user needs.

Through the online configuration tool myPNOZ Creator, users can quickly, intuitively, and accurately configure the security functions they need, and perform simulations to test the logic results. They can also export hardware configuration tables and even wiring references with one click. Compared with the single-function safety relay in the past, it greatly saves the time of selection and learning, improves efficiency and saves cost.

Summary of advantages:

A few simple steps can quickly and accurately match the appropriate safety control system for your two-hand control application. Even if security functions need to be added later, they only need to be added directly on myPNOZ Creator for verification and wiring reference. Isn't this very fragrant?

The power of myPNOZ is far more than that. It has as many as 12 different expansion modules to choose from, and it can even perform simple "AND" and "OR" logic combinations and partition control, etc., which is extremely flexible!